-

产品

新闻

- Locators with bore hole, for spring plungers

- Locators smooth, for spring plungers

- 托座 用于定位柱

- 分割定位柱的迷你分割 有固定凸缘

- 分割定位柱 with locking mechanism push-lock

- 分割螺栓 无螺纹, 有焊接

- Spring Push Plungers 附水平或螺丝凸缘

- 平压花螺帽 DIN 467

- 平压花姆指螺帽 DIN 653

- 高压花的螺母 (有轴环) DIN 466

- 高压花的手转螺丝 DIN 464

- 橡胶金属缓冲器 waisted

- 绞链

- 绞链

- 绞链 elongated on one side

- 绞链 elongated on both sides

- 绞链 长

产品分类- 林业工具

- 配件

- Promotional Boxes

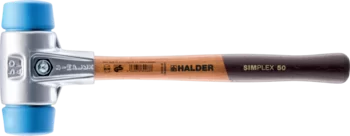

- SIMPLEX软面槌,铸钢外壳

- SIMPLEX 软面锤,加强铸钢外壳

- SIMPLEX软面槌,铝外壳

- SIMPLEX 软面槌, 钢压铸外格, 带有站立功能 "Stand-Up"

- SIMPLEX软面槌,铸铁外壳,50:40

- SIMPLEX 软面槌, 铝外壳 , 50:40

- SIMPLEX soft-face mallets, cast iron housing, extra short handle

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up", extra short handle

- BASEPLEX 木棰

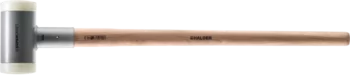

- SIMPLEX大锤,铸钢外壳

- SIMPLEX大锤,钢筋铸钢外壳

- SIMPLEX大锤,铸钢外壳 , 带有站立功能 "Stand-Up"

- SUPERCRAFT 软面槌

- BLACKCRAFT 木棰

- SECURAL 槌子

- SUPERCRAFT 的长柄大槌

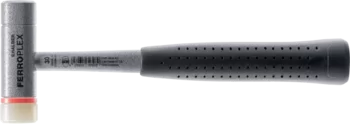

- FERROPLEX 组合槌子

New Items- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with cast iron housing and high-quality wooden handle

- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with aluminium housing and high-quality wooden handle

- SIMPLEX insert, 50:40 TPE-mid, grey

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D60, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D80, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Promotional Box Automotive SIMPLEX soft-face mallet D40, copper / soft metal plus puncher

- BLACKCRAFT Promotional Box Automotive BLACKCRAFT soft-face mallet D60 plus Magnetic Holder

- Promotional Box Dreamteam Door and Window Construction SIMPLEX soft-face mallet 50:40, TPE-soft / TPE-mid and SECURAL plus soft-face mallet

- 服务

- 新闻

- 公司

- 联络

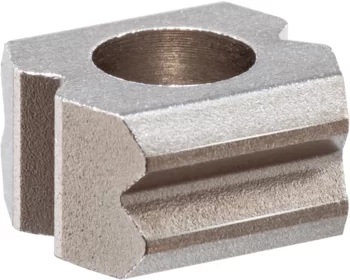

压板支撑零件

EH 23220.

您的选择导致 1 打击

[g]

[g]More details

材质

外壳

- 铝, 红色电镀

本体

- 表面硬化钢,氮化,锰磷酸盐处理和研磨

注意事项

为了安全运行,螺纹孔M 12必须一直关闭。

参考

固定于夹板 23210.0740,可有额外灵活的可能性。

M8规格的螺纹销可以固定于各种定位销和支撑座如 EH 22...。客制化延长版本也可以固定。

夹合高度可以使用高度调整圆柱 EH 23310,以及间隔片 EH 1107 和 EH 1108 来增加。

组装

组装和设置:

固定支撑组件 (2 x M 6 thread) 在装置上。 注意操作者那侧!

替代方法:拆下M 12×10螺纹销更换成一个M12×30螺纹销和用钣手来装配支撑组件(WS21),即T型槽装配(没有明确的操作员一侧保证)。螺纹销M12×30和T-DIN螺母508 M 12×14,质量10,是标准供应量的一部分。

通过16毫米降低支撑组件是可能的。

操作

夹钳過程:

- 通过转动红色保护套外表面上的夹紧凸轮(WS 6内六角),支撑销以轻微的弹簧负载接触工件。

- 通过尽可能接通(锁定),即总共180°,夹紧机构锁定支撑销而不移动。 支撑元件已被放置在工件上并被锁定。

- 如果沿相反方向转动(解锁),夹紧被释放。 如果尽可能地折回,即总共180°,则支撑销移动到终止位置。

更多产品

符合 RoHS

含铅 - 符合例外 6a / 6b / 6c

含有 >0.1% w/w 的 SVHC 物质

含铅 - SVHC [REACH] 清单截至 2024 年 6 月 27 日

包含 65 号提案的物质

铅暴露会导致癌症和生殖伤害

https://www.P65Warnings.ca.gov/

不含冲突矿物

„本产品不含来自刚果民主共和国或邻近国家的任何被指定为“冲突矿物”的物质,例如钽、锡、金或钨。

What are the use cases for the supporting element?

The supporting element can provide additional support at overdetermined clamping points, e.g. on unstable components. It helps reduce vibrations and damage to the surfaces during processing. This improves the surface quality of the workpiece and the service life of the tools dramatically.

What is the force with which the supporting elements makes contact with the workpiece?

The contact force ranges between approx. 20 and 70 N.

Is it possible to change the contact force on the workpiece?

As a customized design, the supporting element can also be manufactured with a different contact force. You are welcome to send us your request if you require such a version.

What is the difference between the supporting elements and floating clamps?

Since the surface is not covered by a clamping claw, it is possible to work on the top and the side surfaces.

Are there alternatives to the supporting element?

The bedding support may be a good and cost-effective alternative. A poor and unprofessional option is the so-called screw jack, also referred to as a “slacker”.

What to do if the supporting element fails to lock?

Here, it is essential to factor in the necessary torque (15Nm). It may not be possible to apply the necessary torque with a hex wrench and T-Handle.

What to do if the supporting element has become damaged?

Repairs are possible in most cases. To arrange for repairs, please contact our sales department.

What type of maintenance / servicing is required on the supporting element?

The supporting element is maintenance-free and does not have to be subjected to special servicing. We do, however, recommend that you regularly perform visual inspections and function tests. You should also pay attention to the oil concentration in the cooling emulsion as the functional parts on the interior may otherwise sustain corrosion.

Contact Form

News

Have a look to our current new parts:

Threaded Lifting Pins with handle Bedding Supports Spring Push Plungers Accessories for spring plungers Index Plungers / Index Bolts Damping Elements Hinges Knurled Nuts / Knurled Thumb Screws