-

产品

新闻

- Locators with bore hole, for spring plungers

- Locators smooth, for spring plungers

- 托座 用于定位柱

- 分割定位柱的迷你分割 有固定凸缘

- 分割定位柱 with locking mechanism push-lock

- 分割螺栓 无螺纹, 有焊接

- Spring Push Plungers 附水平或螺丝凸缘

- 平压花螺帽 DIN 467

- 平压花姆指螺帽 DIN 653

- 高压花的螺母 (有轴环) DIN 466

- 高压花的手转螺丝 DIN 464

- 橡胶金属缓冲器 waisted

- 绞链

- 绞链

- 绞链 elongated on one side

- 绞链 elongated on both sides

- 绞链 长

产品分类- 林业工具

- 配件

- Promotional Boxes

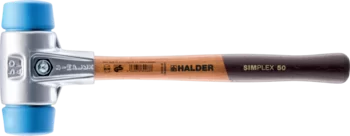

- SIMPLEX软面槌,铸钢外壳

- SIMPLEX 软面锤,加强铸钢外壳

- SIMPLEX软面槌,铝外壳

- SIMPLEX 软面槌, 钢压铸外格, 带有站立功能 "Stand-Up"

- SIMPLEX软面槌,铸铁外壳,50:40

- SIMPLEX 软面槌, 铝外壳 , 50:40

- SIMPLEX soft-face mallets, cast iron housing, extra short handle

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up", extra short handle

- BASEPLEX 木棰

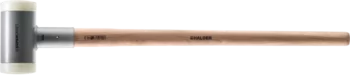

- SIMPLEX大锤,铸钢外壳

- SIMPLEX大锤,钢筋铸钢外壳

- SIMPLEX大锤,铸钢外壳 , 带有站立功能 "Stand-Up"

- SUPERCRAFT 软面槌

- BLACKCRAFT 木棰

- SECURAL 槌子

- SUPERCRAFT 的长柄大槌

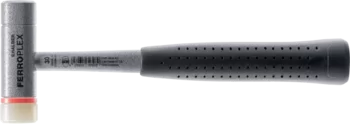

- FERROPLEX 组合槌子

New Items- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with cast iron housing and high-quality wooden handle

- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with aluminium housing and high-quality wooden handle

- SIMPLEX insert, 50:40 TPE-mid, grey

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D60, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D80, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Promotional Box Automotive SIMPLEX soft-face mallet D40, copper / soft metal plus puncher

- BLACKCRAFT Promotional Box Automotive BLACKCRAFT soft-face mallet D60 plus Magnetic Holder

- Promotional Box Dreamteam Door and Window Construction SIMPLEX soft-face mallet 50:40, TPE-soft / TPE-mid and SECURAL plus soft-face mallet

- 服务

- 新闻

- 公司

- 联络

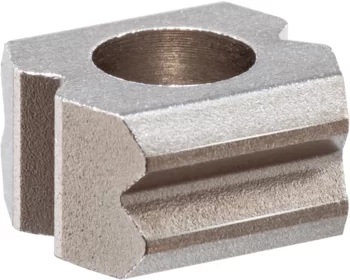

浮动夹具 浮动夹具, 结构紧凑, 分开夹持和锁固, M 12

EH 23320.

您的选择导致 1 打击

[g]

[g]More details

材质

可调节的身体

- 铝,蓝电镀

本体

- 表面硬化钢,氮化,锰磷酸盐处理和研磨

紧固夹钳

- 表面硬化钢,氮化,锰磷酸盐处理

注意事项

对于特定的夹钳情况, 标准的夹钳是可以被交换或替换的 (参见目录图面: 螺丝 ISO 4762 - M8 - 12.9, M max. = 43 Nm)。

组装

- 将浮动夹钳安装到设备上。(安装孔为 M 6,见图纸)

- 使用套筒来调整档块的高度限位和旋转区域,并用固定螺丝(4x WS 2.5)夹紧。在向上设置高度限制时,将会产生较多的空隙 (工件公差)。

操作

1. 向下推动浮动夹具。

2. 向内旋转夹钳。

3. 放鬆浮动夹具。底部的钳口接触带有接触弹簧力的工件。

4. 锁附制具螺母 (WS 18,最大的力矩为15 Nm)。钳口夹持工件 - 此夹具仍然浮动。

5. 然后拧紧六角领螺母 (WS 10,最大的力矩为 10 Nm)

6. 工件夹合过程完成。

7. 释放按相反顺序完成。释放六角领螺母 (WS 10) - 释放六角螺母 (WS 18) - 旋出夹钳。

8. 浮动夹具在最终的定位。

配件

我们提供紧固夹钳作为配件,并且增加其紧固范围。请参考23320.0050-.0058。至于枢轴夹钳,请参考23320.0148-.0156

更多产品

符合 RoHS

含铅 - 符合例外 6a / 6b / 6c

含有 >0.1% w/w 的 SVHC 物质

含铅 - SVHC [REACH] 清单截至 2024 年 6 月 27 日

包含 65 号提案的物质

铅暴露会导致癌症和生殖伤害

https://www.P65Warnings.ca.gov/

不含冲突矿物

„本产品不含来自刚果民主共和国或邻近国家的任何被指定为“冲突矿物”的物质,例如钽、锡、金或钨。

What are the use cases for a floating clamp?

The floating clamp prevents vibrations and the resulting chatter marks on the workpiece. It can be used as an additional clamping device, supplementing the support provided by the three standard clamping points. This will not lead to overdetermination of the component.

Which benefits arise from using floating clamps in manufacturing?

The floating clamps allow for additional clamping points during the first step of processing, preventing the formation of vibrations. This improves the surface quality of the workpiece and the service life of the tools dramatically. A secure working process is thus guaranteed.

What is the difference between the red and the blue floating clamps?

The red floating clamps clamp and lock the workpiece in a single work step. The blue floating clamps allow you to clamp and lock the workpiece separately. The latter are used predominantly on thin and unstable workpieces.

What advantage does the floating clamp hold over bedding supports and supporting elements?

Aside from supporting the workpiece, the floating clamp also clamps it from the top.

What is the benefit of a floating clamp compared to a trestle with clamps?

The spring load with which the floating clamp makes contact with the workpiece is always the same. This keeps the workpiece from bending and eliminates the need to resort to cumbersome and time-consuming clamping with the help of a dial gauge. It furthermore impresses with its compact design and effortless ease of use. Notwithstanding, the fastening on the machine table still ensures utmost stability.

Does the floating clamp provide positional repeatability?

It is possible to set the floating clamps to the required swivel range and height thanks to the colour-coded body.

What do you have to take into consideration when using the floating clamp?

You need to factor in the maximum permissible torque when clamping the workpiece. The specifications are printed on the stop sleeve and can also be found in the catalogue. You should also pay attention to the oil concentration in the cooling emulsion as the functional parts on the interior may otherwise sustain corrosion.

How much contact force does the lower clamping jaw exert on the workpiece?

The contact force of floating clamps 23320.0008 and 23320.0010 ranges from approx. 18 to 42 N. For the 23320.0012 and the 23320.0014 it lies between approx. 19 and 27 N, while the range for the 23320.0016 is approx. 73 to 99 N.

Is it possible to attach longer custom jaws at the floating clamps and, if so, what is the maximum length?

The floating clamp does allow for the attachment of custom jaws. However, their length is limited by the laws of physics and varies, first and foremost, with the strength of the material. Custom jaws with an overhanging length of 73 mm have already been realised. However, proper function cannot be guaranteed if you use custom jaws. The blue floating clamp is strongly recommended for the use of longer custom jaws on parts that are sensitive to bending. It is also vital to ensure that the mounting screws of the upper clamping jaw and of the lower clamping jaw are screwed into the housing, respectively, by 10 mm and by 9 mm. We also ask that you follow the instructions on assembly and any other information on the clamping jaws given in the catalogue.

What type of repair / maintenance is required on the floating clamp?

The floating clamp is maintenance-free and does not have to be subjected to special servicing. We do, however, recommend that you regularly perform visual inspections and function tests.

What to do of the floating clamp has become damaged?

Repairs are possible in most cases. To arrange for repairs, please contact our sales department.

Is the floating clamp limited to use inside Halder’s T-slot system V70?

The floating clamp can be used across the entire range of fixture construction. You can choose from two available size versions - M12 and M16. The flange-mounted floating clamps offer an additional fastening option. These options are listed on the datasheet of each individual floating clamp.

Contact Form

News

Have a look to our current new parts:

Threaded Lifting Pins with handle Bedding Supports Spring Push Plungers Accessories for spring plungers Index Plungers / Index Bolts Damping Elements Hinges Knurled Nuts / Knurled Thumb Screws