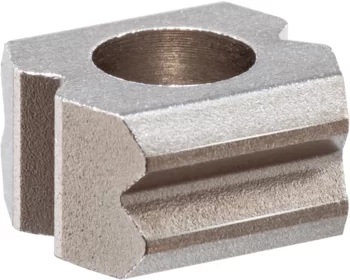

螺纹顶上销 自锁,用于根据DIN 332的中心孔

EH 22352.

当有一个带有根据DIN 332的沉头孔的螺纹孔时,使用此螺纹起重销。

重型提升元件,易于快速使用,带有可移动的卸扣和锁紧螺柱,可防止意外解锁。对于起吊负载,将带螺纹的起重销插入螺纹孔中。与环形螺栓相反,因此不需要费时的旋入和旋出。

所有版本皆有侵蚀保护。不鏽钢版本也有抗侵蚀和风化的能力,所以也适合在户外使用。此外,高强度的沉淀硬化销让极端的负载成为可能。 。

您的选择导致 12 打击

More details

- 热处理钢

- d1: M8

- l1: 13,9 mm

- d2 -0,07: 6,62 mm

- d3: 21,5 mm

- d4: 8,1 mm

- l2: 17,6 mm

- l3: 19,5 mm

- l4: 34,6 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 82,3 mm

- l9: 21,5 mm

- l10: 8 mm

- 負載能力 根據 DIN EN 13155 F1: 2,1 kN

- 負載能力 根據 DIN EN 13155 F2: 0,9 kN

- 負載能力 根據 DIN EN 13155 F3: 0,8 kN

- 定位螺牙: M8

- Operating temperature range max. : 250 °C

- 重量: 227 g

- 热处理钢

- d1: M10

- l1: 16 mm

- d2 -0,07: 8,35 mm

- d3: 21,5 mm

- d4: 10,2 mm

- l2: 20 mm

- l3: 22,9 mm

- l4: 36,4 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 83,6 mm

- l9: 21,5 mm

- l10: 10 mm

- 負載能力 根據 DIN EN 13155 F1: 3,9 kN

- 負載能力 根據 DIN EN 13155 F2: 1,5 kN

- 負載能力 根據 DIN EN 13155 F3: 1,5 kN

- 定位螺牙: M10

- Operating temperature range max. : 250 °C

- 重量: 274 g

- 热处理钢

- d1: M12

- l1: 19 mm

- d2 -0,07: 10,07 mm

- d3: 21,5 mm

- d4: 12,7 mm

- l2: 24 mm

- l3: 28,1 mm

- l4: 39,1 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 84,3 mm

- l9: 21,5 mm

- l10: 12 mm

- 負載能力 根據 DIN EN 13155 F1: 6,2 kN

- 負載能力 根據 DIN EN 13155 F2: 2,5 kN

- 負載能力 根據 DIN EN 13155 F3: 2,3 kN

- 定位螺牙: M12

- Operating temperature range max. : 250 °C

- 重量: 249 g

- 热处理钢

- d1: M16

- l1: 19 mm

- d2 -0,07: 13,8 mm

- d3: 21,5 mm

- d4: 16,7 mm

- l2: 25 mm

- l3: 30,5 mm

- l4: 42,3 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 88,5 mm

- l9: 21,5 mm

- l10: 12 mm

- 負載能力 根據 DIN EN 13155 F1: 8,4 kN

- 負載能力 根據 DIN EN 13155 F2: 4,5 kN

- 負載能力 根據 DIN EN 13155 F3: 4,2 kN

- 定位螺牙: M16

- Operating temperature range max. : 250 °C

- 重量: 271 g

- 热处理钢

- d1: M20

- l1: 25 mm

- d2 -0,07: 17,75 mm

- d3: 30 mm

- d4: 20,7 mm

- l2: 31,8 mm

- l3: 39,1 mm

- l4: 53,7 mm

- l5: 32,6 mm

- l6: 36 mm

- l7: 56 mm

- l8: 109,2 mm

- l9: 30 mm

- l10: 17 mm

- 負載能力 根據 DIN EN 13155 F1: 16,6 kN

- 負載能力 根據 DIN EN 13155 F2: 7,7 kN

- 負載能力 根據 DIN EN 13155 F3: 5,8 kN

- 定位螺牙: M20

- Operating temperature range max. : 250 °C

- 重量: 554 g

- 热处理钢

- d1: M24

- l1: 31 mm

- d2 -0,07: 20,7 mm

- d3: 36 mm

- d4: 24,7 mm

- l2: 38,9 mm

- l3: 47,3 mm

- l4: 61,4 mm

- l5: 50,6 mm

- l6: 49,8 mm

- l7: 82 mm

- l8: 145,4 mm

- l9: 36 mm

- l10: 22 mm

- 負載能力 根據 DIN EN 13155 F1: 23 kN

- 負載能力 根據 DIN EN 13155 F2: 11,1 kN

- 負載能力 根據 DIN EN 13155 F3: 8,6 kN

- 定位螺牙: M24

- Operating temperature range max. : 250 °C

- 重量: 1234 g

- 不锈钢

- d1: M8

- l1: 13,9 mm

- d2 -0,07: 6,62 mm

- d3: 21,5 mm

- d4: 8,1 mm

- l2: 17,6 mm

- l3: 19,5 mm

- l4: 34,6 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 82,3 mm

- l9: 21,5 mm

- l10: 8 mm

- 負載能力 根據 DIN EN 13155 F1: 2,1 kN

- 負載能力 根據 DIN EN 13155 F2: 0,9 kN

- 負載能力 根據 DIN EN 13155 F3: 0,8 kN

- 定位螺牙: M8

- Operating temperature range max. : 250 °C

- 重量: 227 g

- 不锈钢

- d1: M10

- l1: 16 mm

- d2 -0,07: 8,35 mm

- d3: 21,5 mm

- d4: 10,2 mm

- l2: 20 mm

- l3: 22,9 mm

- l4: 36,4 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 83,6 mm

- l9: 21,5 mm

- l10: 10 mm

- 負載能力 根據 DIN EN 13155 F1: 3,9 kN

- 負載能力 根據 DIN EN 13155 F2: 1,5 kN

- 負載能力 根據 DIN EN 13155 F3: 1,5 kN

- 定位螺牙: M10

- Operating temperature range max. : 250 °C

- 重量: 274 g

- 不锈钢

- d1: M12

- l1: 19 mm

- d2 -0,07: 10,07 mm

- d3: 21,5 mm

- d4: 12,7 mm

- l2: 24 mm

- l3: 28,1 mm

- l4: 39,1 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 84,3 mm

- l9: 21,5 mm

- l10: 12 mm

- 負載能力 根據 DIN EN 13155 F1: 6,2 kN

- 負載能力 根據 DIN EN 13155 F2: 2,5 kN

- 負載能力 根據 DIN EN 13155 F3: 2,3 kN

- 定位螺牙: M12

- Operating temperature range max. : 250 °C

- 重量: 249 g

- 不锈钢

- d1: M16

- l1: 19 mm

- d2 -0,07: 13,8 mm

- d3: 21,5 mm

- d4: 16,7 mm

- l2: 25 mm

- l3: 30,5 mm

- l4: 42,3 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 88,5 mm

- l9: 21,5 mm

- l10: 12 mm

- 負載能力 根據 DIN EN 13155 F1: 8,4 kN

- 負載能力 根據 DIN EN 13155 F2: 4,5 kN

- 負載能力 根據 DIN EN 13155 F3: 4,2 kN

- 定位螺牙: M16

- Operating temperature range max. : 250 °C

- 重量: 271 g

- 不锈钢

- d1: M20

- l1: 25 mm

- d2 -0,07: 17,75 mm

- d3: 30 mm

- d4: 20,7 mm

- l2: 31,8 mm

- l3: 39,1 mm

- l4: 53,7 mm

- l5: 32,6 mm

- l6: 36 mm

- l7: 56 mm

- l8: 109,2 mm

- l9: 30 mm

- l10: 17 mm

- 負載能力 根據 DIN EN 13155 F1: 10 kN

- 負載能力 根據 DIN EN 13155 F2: 7,7 kN

- 負載能力 根據 DIN EN 13155 F3: 5,8 kN

- 定位螺牙: M20

- Operating temperature range max. : 250 °C

- 重量: 555 g

- 不锈钢

- d1: M24

- l1: 31 mm

- d2 -0,07: 20,7 mm

- d3: 36 mm

- d4: 24,7 mm

- l2: 38,9 mm

- l3: 47,3 mm

- l4: 61,4 mm

- l5: 50,6 mm

- l6: 49,8 mm

- l7: 82 mm

- l8: 145,4 mm

- l9: 36 mm

- l10: 22 mm

- 負載能力 根據 DIN EN 13155 F1: 23 kN

- 負載能力 根據 DIN EN 13155 F2: 11,1 kN

- 負載能力 根據 DIN EN 13155 F3: 8,6 kN

- 定位螺牙: M24

- Operating temperature range max. : 250 °C

- 重量: 1234 g

材质

梢子零件

- 热处理钢、锻炼的、磷酸锰

- 不锈钢 1.4542、沉淀硬化

按钮

- 铝,橘色,阳极

螺纹元件

- 不锈钢 1.4542、沉淀硬化

钩环

- 热处理钢、锻炼的、磷酸锰

- 不锈钢 1.4571

弹簧

- 不锈钢

组装

可以将带螺纹的起重销安装到符合规格的螺纹中。

安装:

- 按下按钮并按住

- 插入带螺纹的起重销

- 释放按钮(按钮必须回到其原始位置。)

- 用手拧紧带螺纹的起重销,直到其完全紧贴在轴承表面上。

- 必须确保将螺纹段嵌入安装螺纹中。

拆解:

- 大约拧松带螺纹的起重销逆时针旋转四分之一圈。

- 按下按钮并按住

- 卸下带螺纹的吊销

- 释放按钮

操作

每一個螺紋吊升銷都包含一個使用手冊,和EC聲明。

更多产品

符合 RoHS

含铅 - 符合例外 6a / 6b / 6c

含有 >0.1% w/w 的 SVHC 物质

含铅 - SVHC [REACH] 清单截至 2024 年 6 月 27 日

包含 65 号提案的物质

铅暴露会导致癌症和生殖伤害

https://www.P65Warnings.ca.gov/

不含冲突矿物

„本产品不含来自刚果民主共和国或邻近国家的任何被指定为“冲突矿物”的物质,例如钽、锡、金或钨。

What is the function of threaded lifting pins and in which industry are they used?

Any components, machines and workpieces with an existing thread can be lifted or secured directly via the thread. The threaded lifting pins are used in almost all industries, e.g. in mechanical engineering, electrical industry, fixture construction and assembly.

What is the difference between lifting pins and threaded lifting pins?

The lifting pins can be mounted very quickly in existing bores with undercut.

Components that already have an existing thread can be moved or lifted with the threaded lifting pin by inserting the threaded lifting pin into the threaded hole.

Previously used eyebolts can be replaced with the Halder threaded lifting pin without any problems or mechanical changes to the component - please refer to the load specifications in the catalogue.

What is the advantage of the threaded lifting pin compared to eyebolts?

Eyebolts are cheaper, but they remain on the parts to be moved. In the long run, this is very noticeable in the price. It takes time to tighten the eyebolts. In comparison, the threaded lifting pins are inserted into the thread and locked "in one go" by pressing the actuating button. For this reason, the threaded lifting pin is amortised after approx. 350 applications.

What must be considered when mounting the threaded lifting pins?

As this is a TÜV-certified load handling device with CE labelling, the operating instructions must be observed. The threaded lifting pin must always be inserted completely into the thread. In addition, functional safety is ensured by turning it slightly by hand until it reaches the thread stop.

In which thread sizes is the threaded lifting pin available?

In sizes M8, M10, M12, M16, M20, M24, M27, M30 as well as 1/2", 3/4" and 1".

What is the maximum axial load to which the threaded lifting pins may be subjected?

The maximum load capacity varies with the version used. The values - tested in accordance with DIN EN 13155 - range from 2.1 kN (M8) to 42.3 kN (M30). The values range lower for a diagonal pull / tensile direction of 90° - see product data table.

Are customized designs also possible for threaded lifting pins?

Yes, customized designs are possible. However, since thread segments are required for each thread size in the case of the threaded lifting pins, only the existing thread sizes can be offered at the moment. Changes to the geometry can be made up to a certain point. Please send us your enquiry if required.

What has to be considered for a customized design of a threaded lifting pin?

As the customized designs are only similar to the standard versions, TÜV approval is not applicable.

If the deviation from the standard version is only minimal, CE labelling may be possible. In this way, the customised part also receives a load capacity specification based on the equivalent standard part.

Starting from which number of pieces can a special geometry be produced for the threaded lifting pins?

An economic offer can be provided for a minimum of 10 pieces. Please feel free to send us your enquiry if required.

What is the difference between the TÜV certificate and the CE labelling for ball lock and threaded lifting pins?

As the threaded lifting and ball lock pins are a load handling device and therefore fall within the machinery directive 2006/42/EC, CE labelling is compulsory. The CE labelling includes, among other things, that a maximum lifting capacity of the ball lock / threaded lifting pin is specified. This information is determined by internal calculations and tests. The ball lock / threaded lifting pin is only approved by the TÜV if these values have also been tested and approved by the TÜV. Special designs are only manufactured as special pins without CE labelling and thus without specification of the lifting capacity, as no tests and calculations are usually carried out for these. If applicable, a CE labelling can be issued if the ball lock / threaded lifting pin is similar to a standard lifting pin and its load data can be used as a reference. A TÜV certificate must be specially ordered from the TÜV for each size for testing and is associated with additional costs. Please send us your enquiry if required.

Does the information on the threaded lifting pins indicate the production lot?

Yes, in addition to the annual production date, the Batch number BA is also indicated on the lifting pin.

Of what materials are the threaded lifting pins made?

There is a version made of heat-treated steel, tempered and manganese phosphated and a version made of stainless steel 1.4542 precipitation-hardened, depending on the application. For load values see product data chart.

What is the lifetime of a threaded lifting pin?

This cannot be answered in a general way, as it always depends on the application and the surrounding conditions. If a threaded lifting pin is damaged, e.g. if it is cracked or deformed, it must be removed from use immediately. This visual and functional check must be carried out before each use. Furthermore, the threaded lifting pin must be subjected to a safety check once a year with a visual and functional check by a qualified person.