Advanced tools help save resources and add flexibility and economy

Danger is all around in the crafts sector. Accidents at work - both great and small - happen nearly every day. Tests have shown: The premium soft-face mallets made by Erwin Halder KG diminish the danger inherent in many high-risk situations. As an added benefit, they streamline the daily work routine, preserve the workpiece and often shorten the work time and lower cost.

Every strike is accompanied by a loud and lingering bang, and the vibrations it causes can be felt not only in the air. When steel hits steel, you will feel the reverberations in your blood and in your bones. The effects are more than just unpleasant: “The loud volume may cause permanent damage to your hearing. The violent rebound and the vibrations generated at the handle put extreme strain on the muscles, joints and sinews in arms and shoulders. In more cases than not, this will result in painful inflammations. Meanwhile, the tremendous rebound also reduces the impact force by no small degree, making it necessary to increase the number of strikes to achieve the desired outcome. This makes the work unnecessarily exhausting. However, by far the greatest risk during steel-on-steel strikes is posed by metal splinters that may break off on impact and cause serious injuries”, states Volker Gernth, Sales Director Hand Tools at Erwin Halder KG, describing the risks involved for craftsmen when using hammers with hardened steel head on steel workpieces, steel edges, framing, steel beams, rail tracks or similar materials.

Minimise risk by opting for a SUPERCRAFT, SECURAL or BLACKCRAFT

Halder soft-face mallets provide a remedy. This has now been confirmed in a recent expert report carried out by the Büttelborn “Engineering Office for Ergonomics”: The tests performed by the engineers focused on three non-rebound mallets made by Erwin Halder KG: the SUPERCRAFT, the SECURAL, and the BLACKCRAFT. They owe their non-rebound properties to their steel shot filling.

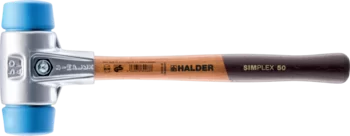

Its inserts made of special nylon, its robot-welded handle protection sleeve and its vibration-dampening hickory handle make the SUPERCRAFT ideal for sheet-metal work such as assembly and repair work in the passenger car and commercial vehicle sector, the positioning and joining of workpieces, the assembly of sharp-edged workpieces, straightening work, housing assembly, plant construction, and maintenance work.

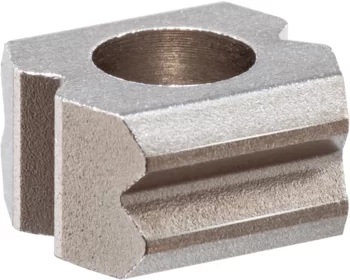

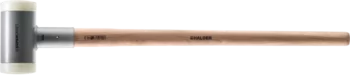

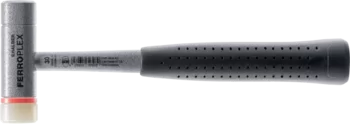

When it comes to working on corners and edges, the SECURAL is given a decisive edge by its replaceable rectangular inserts made of polyurethane. The BLACKDRAFT hammer with its PUR-encased steel tube housing and ergonomically shaped rubber handle is used primarily for work on workpieces that are particularly sensitive.

When pitted against a conventional 500 g locksmith’s hammer in the tests performed by the engineering office, the three soft-face mallets managed to lower the perceived volume during a strike on an aluminium hollow profile by a substantial degree: by 41.4 per cent for SUPERCRAFT, by 60.8 per cent for the SECURAL, and by an astounding 63.4 for the BLACKDRAFT. Welcome relief for your ears! Another significant reduction the soft-face mallets delivered compared to the locksmith’s hammer could be witnessed in the strain caused by the rebound after a strike on an impact plate made from steel: The engineering office measured decreases in vibration on the handle of 48.7 per cent, 57.2 per cent and 58.7 per cent for the SUPERCRAFT, the SECURAL, and the BLACKDRAFT, respectively. Conversely, the SUPERCRAFT produced an impact force during a strike on an aluminium impact plate that was 13.7 per cent greater than that of a locksmith`s hammer, while the SECURAL was on par with the locksmith`s hammer in this area. While the impact force generated by the BLACKDRAFT was slightly lower by 4.9 per cent, the product was found to be much gentler on both the workpieces and the user.

“We also managed to eliminate any danger from metal splinters breaking off, as the inserts we use in our soft-face mallets are softer than the material they process. However, while softer than other inserts, the nylon inserts of the SUPERCRAFT mallet are exceptionally wear-resistant. Tests have shown that they also hold up to strikes on steel edges - even in temperatures below freezing”, reveals Volker Gernth.

High-quality materials ensure longevity and safety

Using only the finest materials for the production of their soft-face mallets is the most sacred principle at Halder: The high-quality wooden handles are crafted from hickory / acacia. The long fibres of these types of wood make the handles more break-proof and, thus, much safer than the ash handles commonly found on the market. If the wooden handle of a hammer breaks during a strike, there is a risk of the hammer head causing serious injury. What is more, the handle protection sleeves keep the handle safe from damage in case of mis-strikes. Even better: The ergonomic shape of both the wooden handles and the rubber grips lets the tool contour perfectly to the user’s hand. This keeps the soft-face mallet from ever slipping out of your hand.

All housings of the soft-face mallets are ultra stable and break-proof. Since the welding operations are executed by robots, the tools are guaranteed to be of consistently high quality. This manufacturing process also keeps the steel shot filled into the hammer head perfectly sealed and protects it from corrosion by a thick layer of power coating.

Volker Gernth: “Aside from protecting the craftsman, the soft-face mallets preserve the workpiece that is being processed and keep it from becoming damaged. As an added plus, they do away with the need for cumbersome striking blocks. Picking the soft-face mallet that is best for the application at hand will leave sensitive boards / tiles, glass panes and wooden parts fully intact. There will be no scratches or defects on sensitive surfaces, such as those found on light metal wheel rims. Even undesired marring on such bright materials as natural stone or wood is now a thing of the past with the right choice of insert. This helps save time and cost as it makes repair work entirely unnecessary.”

The right soft-face mallet for any type of application

Especially the product that started it all for Erwin Halder AG, the SIMPLEX soft-face mallet, offers a myriad of inserts. Users can select from eight different types of insert materials. They are therefore sure to find the right solution for any application. The inserts made of composite rubber will, for instance, last much longer than an ordinary rubber mallet. And, thanks to the SIMPLEX principle, the user will enjoy ultimate flexibility, economy and preservation of resources as all individual parts - handle, housing and inserts - can be replaced separately.

Volker Gernth concludes: “Our soft-face mallets play in a league of their own: They make work safer and more effortless and efficient. They keep the user safe, are gentle on the material and lay the foundation for work results of excellent quality. This verdict is not our conviction alone, but has been corroborated in numerous comparative tests and in millions of use cases in the real world.”

Halder’s soft-face mallets, such as the SUPERCRAFT, minimise the risks to the user’s health.

Halder’s soft-face mallets make it possible to reduce the perceived volume substantially.

Halder’s non-rebound soft-face mallets generate much less vibration and thereby carry lower health risks.

Despite the reduced volume and minimised vibration, the impact force of the SUPERCRAFT even exceeds that of a locksmith`s hammer.

The BLACKCRAFT along with all other Halder soft-face mallets keep such damage as scratches and defects off sensitive surfaces.

Halder’s selection of hammers is sure to offer every craftsman the right solution for any of their applications.

Downloads: