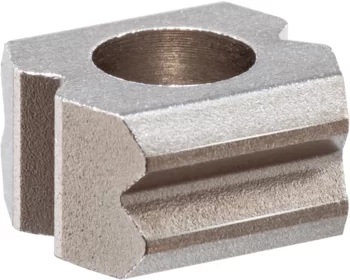

22356.1104 - Threaded Lock Pins

self-locking, with axial bearing

Threaded lock pins are used for quick fastening, locking, adjusting, changing, clamping, connecting and securing. Quickly and easily unlockable for frequently repeated connections.

By pressing the button, the threaded segments unlock and the threaded lock pin can be inserted into or removed from a threaded hole. A time-consuming screwing in and out is unnecessary.

The thread lock pin is characterised by the following features and advantages:

- Corrosion-protected

- No time-consuming screwing in and unscrewing

- Self-locking due to spring force

- With axial bearing

The advantages of the axial bearing:

- Double clamping force with the same grip size by reducing surface friction.

- Protection of the component due to fixed contact surface.

- Low setting behaviour due to higher pretensioning force in the bolt or thread.

- Less force required to release.

This article 22356.1104 - Threaded Lock Pins self-locking, with axial bearing / (d1: M8, l1: 20 mm) is one variant of the article group Threaded Lock Pins self-locking, with axial bearing (EH 22356.)

More details

- Stainless steel

- d1: M8

- l1: 20 mm

- d2 -0.07: 6.62 mm

- d3: 40 mm

- d4: 30 mm

- l2: 33.8 mm

- l3: 82.2 mm

- l4: 8 mm

- Locating thread: M8

- Operating temperature range min.: -30 °C

- Operating temperature range max.: 80 °C

- Tightening torque max.: 5 Nm

- Clamping force max.: 4.8 kN

- Established tightening torque ~1): 3.5 Nm

- Clamping force ~2): 3.3 kN

- Weight: 98 g

- Shearing resistance, two-shear3) min.: 36.4 kN

Material

Pin part

- Stainless steel 1.4542, precipitation-hardened

Handle

- Thermoplastic PA 6, black, dull similar to RAL 9005

Press button

- Aluminium, orange, anodised

Threaded element

- Stainless steel 1.4542, precipitation-hardened

Axial bearing

- Stainless steel

Spring

- Stainless Steel

Notes

Special types on request.

Due to the thread geometry, the clamping force is higher with the smaller thread sizes.

Assembly

Threaded lock pins can only be mounted into a thread that is true to gauge.

Mounting:

- Press in the button and hold it down.

- Insert the threaded lock pin.

- Release the button (The button must be back in its original position.).

- Tighten the threaded lock pin by hand as required.

- It must be ensured that the threaded segments are engaged in the mounting thread.

Dismantling:

- Unscrew the threaded lock pin approx. a quarter of a turn anticlockwise.

- Press in the button and hold it down.

- Remove the threaded lock pin.

- Release the button.

Operation

The threaded segments are unlocked by pressing the button.

Additional variants of this article

Accessories

Can easily be fitted with retaining cable EH 22355.

Further products

RoHS compliant

Contains lead - compliant according to exceptions 6a / 6b / 6c.

Contains SVHC substances >0,1% w/w

Contains lead - SVHC list [REACH] as of 27.06.2024.

Contains Proposition 65 substances

Lead can cause cancer and reproductive harm from exposure

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.