„The SIMPLEX mallet is a masterpiece!“

Different inserts matched perfectly for every application

Is the rim or the brake drum not coming off the wheel hub? Is a bearing stuck? Do you need to remove / attach the locking pins of the brake callipers? Is the strut supposed to be removed from the axle journal? Mallets are staple tools used daily in every car workshop. Aside from delivering the necessary impact force and durability, the tools need to guarantee perfect safety during use and be gentle on the material. Erwin Halder KG’s selection offers the right mallet for any type of application. Schloss Werkstatt in Heidenheim is among the many who have come to appreciate the advantages of these striking tools.

Whether they repair vehicles after an accident or perform routine daily tasks - every workshop requires tools that are of the highest possible quality - a conviction that is held by Stefan Frey, master car mechanic and owner of the Schloss Werkstatt car workshop. Operating in the heart of Heidenheim as an independent workshop, the business has been servicing and repairing automobiles of all types - with a special focus on luxury cars - since 2014. Stefan Frey is unwilling to compromise when it comes to the tools and equipment utilised at his workshop. The only mallets he trusts are those made by Erwin Halder KG, e.g. SIMPLEX soft-face mallets.

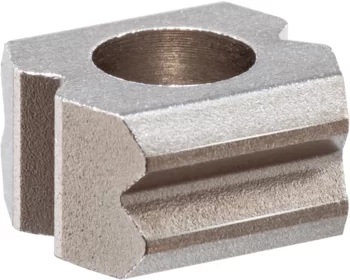

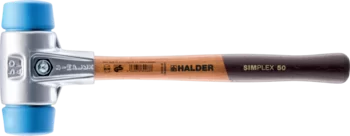

Perfectly matched and fine-tuned to one another based on the SIMPLEX principle, the individual components – handle, housing and inserts – can be replaced separately as needed. Their exchangeable inserts with different degrees of hardness allow the worker to perfectly match the mallet to the part and the job at hand. “Another benefit of this mallet is its comparatively affordable price”, declares Stefan Frey.

Ample power – even in the smallest of spaces

Schloss Werkstatt uses two versions of the mallet: the SIMPLEX mallet with inserts made of black rubber composite and red plastic as their standard tool as well as the model that comes with a copper and soft metal insert. The combination of copper and soft metal insert, fibre glass handle and reinforced cast steel housing can handle extremely hard blows and is exceptionally rugged and durable. Its increased weight alone improves the mallet's impact force substantially. “Especially the mallet with the copper and soft metal insert has been our standard daily tool for about two years. Using it is actually loads of fun”, Stefan Frey rejoices. “This mallet lets you exert much greater force than the red-black model. This proves beneficial, for instance, if the lower ball joint has seized. The tool allows you to apply the necessary impact force in the tight wheel case to loosen the parts with a strike on the lowered transverse control arm.”

The ergonomically shaped fibre glass handle contours perfectly to your hand and will not slip. Another quality that makes it perfect for workshop environments is its resistance to moisture. “Also of key importance from a health and safety standpoint is that the inserts will not splinter. This reduces the risk of accidents. This mallet is an absolute masterpiece”, adds Stefan Frey.

Maximum impact force

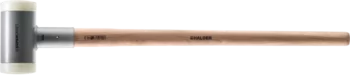

Another tool Schloss Werkstatt depends on is the SUPERCRAFT mallet engineered by Erwin Halder KG. The energy of the steel shot in its tubular head is transferred with a slight delay when the mallet's contact surface hits the workpiece. The reduced rebound allows the impact energy to be absorbed with perfect efficiency, resulting in an extremely powerful impact. “This quality makes it possible, for instance, to remove a wheel hub from the axle journal with just a few targeted strikes. The ergonomically shaped 3-component handle ensures a firm grip even with fingers that are usually dirty from your daily work at the auto shop”, explains Stefan Fry. “Another key asset are the exchangeable nylon inserts: They are hard, very wear-resistant and resistance to breakage. You will not have to worry about splinters breaking off even if you hit an edge with maximum force. This is a crucial factor for safety at work.”

Other advantages SUPERCRAFT mallets possess over ordinary steel mallets are the reduced strain they put on the user’s joints and the low noise level they generate.

Maximum power, complete control

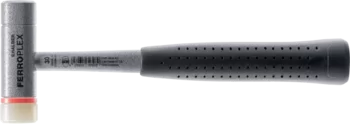

Another major part of the daily routine in a car workshop is changing wheels. A common problem the mechanics experience is that the wheel cannot be pulled off the hub despite the loosened bolts. Stefan Frey’s comment on the matter: “This issue is extremely time-consuming and unnerving - especially when we need to change one wheel after another. In the BLACKCRAFT mallet by Halder we found the solution that put an end to this problem quickly and in a way that is gentle on the rim. It offers two monumental advantages: Non-rebound striking and a polyurethane casing. If you strike the inside of the rim with the mallet to detach it, you can apply a relatively large amount of force without damaging the rim, and the rim will come off in no time flat.”

The soft-face mallets engineered by Erwin Halder KG have become indispensable at Schloss Werkstatt and have proven their worth countless times in other car and commercial vehicle workshops as well as during repairs and maintenance work.

Since they are made available with eight inserts made of premium materials - from soft to hard, other industries are also sure to find the mallet that fits their specific needs best. One example are gardening and landscaping businesses, where the black-white - rubber composite and superplastic - insert combination is a popular choice on account of its outstanding abilities during curbstone setting and paving.

If the wheel refuses to come off the hub, Stefan Frey trusts in his go-to tool: Halder's BLACKCRAFT mallet.

It allows him to apply a relatively large amount of force without damaging the rim.

The SUPERCRAFT mallet's reduced rebound allows the impact energy to be absorbed with perfect efficiency, resulting in an extremely powerful impact.

An additional benefit: The nylon inserts will never splinter - even if used for forceful strikes onto hard edges.

Downloads: