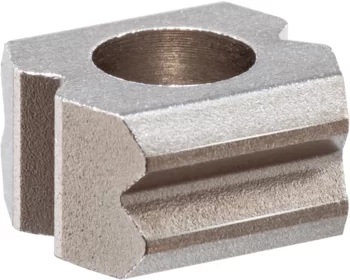

Lifting Pins self-locking

EH 22350.

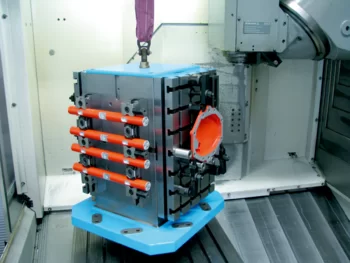

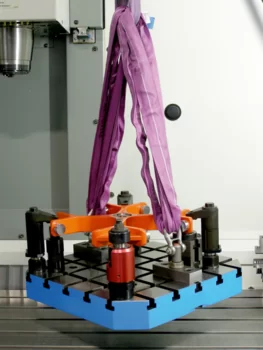

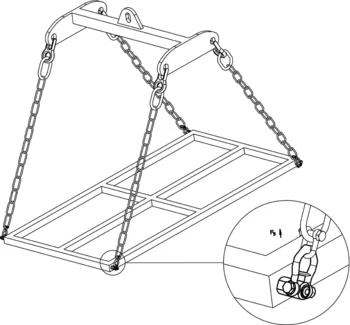

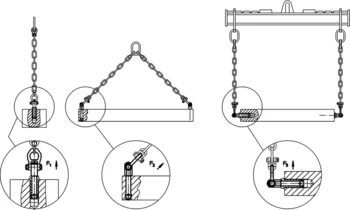

Heavy-duty lifting element for quick and easy use, with moveable shackle and locking stud to provide protection against unintentional unlocking. Special lifting devices, e.g. threads for ring bolts, are no longer required on the workpiece.

All versions are corrosion-resistant.

Your selection resulted in 24 hits

More details

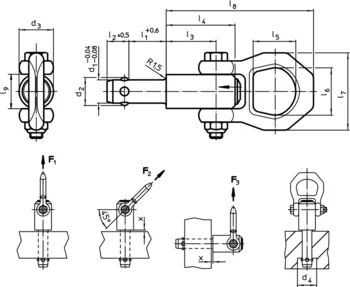

- d1 -0.04 -0.08: 8 mm

- l1 +0.6: 10 mm

- d2: 9.35 mm

- d3: 21.5 mm

- d4 min.: 9.85 mm

- l2 ±0.5: 8.75 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 1.5 kN

- Load capacity according to DIN EN 13155 F2: 1.2 kN

- Load capacity according to DIN EN 13155 F3: 0.5 kN

- x min.: 1.5 mm

- x max.: 5 mm

- Location hole H11: 8 mm

- Operating temperature range max.: 250 °C

- Weight: 266 g

- d1 -0.04 -0.08: 8 mm

- l1 +0.6: 15 mm

- d2: 9.35 mm

- d3: 21.5 mm

- d4 min.: 9.85 mm

- l2 ±0.5: 8.75 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 1.5 kN

- Load capacity according to DIN EN 13155 F2: 1.2 kN

- Load capacity according to DIN EN 13155 F3: 0.5 kN

- x min.: 1.5 mm

- x max.: 10 mm

- Location hole H11: 8 mm

- Operating temperature range max.: 250 °C

- Weight: 269 g

- d1 -0.04 -0.08: 8 mm

- l1 +0.6: 25 mm

- d2: 9.35 mm

- d3: 21.5 mm

- d4 min.: 9.85 mm

- l2 ±0.5: 8.75 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 1.5 kN

- Load capacity according to DIN EN 13155 F2: 1.2 kN

- Load capacity according to DIN EN 13155 F3: 0.5 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 8 mm

- Operating temperature range max.: 250 °C

- Weight: 270 g

- d1 -0.04 -0.08: 8 mm

- l1 +0.6: 35 mm

- d2: 9.35 mm

- d3: 21.5 mm

- d4 min.: 9.85 mm

- l2 ±0.5: 8.75 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 1.5 kN

- Load capacity according to DIN EN 13155 F2: 1.2 kN

- Load capacity according to DIN EN 13155 F3: 0.5 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 8 mm

- Operating temperature range max.: 250 °C

- Weight: 278 g

- d1 -0.04 -0.08: 8.3 mm

- l1 +0.6: 10 mm

- d2: 9.65 mm

- d3: 21.5 mm

- d4 min.: 10.05 mm

- l2 ±0.5: 8.75 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 1.5 kN

- Load capacity according to DIN EN 13155 F2: 1.2 kN

- Load capacity according to DIN EN 13155 F3: 0.5 kN

- x min.: 1.5 mm

- x max.: 5 mm

- Location hole H11: 8.3 mm

- Operating temperature range max.: 250 °C

- Weight: 266 g

- d1 -0.04 -0.08: 8.3 mm

- l1 +0.6: 15 mm

- d2: 9.65 mm

- d3: 21.5 mm

- d4 min.: 10.05 mm

- l2 ±0.5: 8.75 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 1.5 kN

- Load capacity according to DIN EN 13155 F2: 1.2 kN

- Load capacity according to DIN EN 13155 F3: 0.5 kN

- x min.: 1.5 mm

- x max.: 10 mm

- Location hole H11: 8.3 mm

- Operating temperature range max.: 250 °C

- Weight: 266 g

- d1 -0.04 -0.08: 8.3 mm

- l1 +0.6: 25 mm

- d2: 9.65 mm

- d3: 21.5 mm

- d4 min.: 10.05 mm

- l2 ±0.5: 8.75 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 1.5 kN

- Load capacity according to DIN EN 13155 F2: 1.2 kN

- Load capacity according to DIN EN 13155 F3: 0.5 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 8.3 mm

- Operating temperature range max.: 250 °C

- Weight: 273 g

- d1 -0.04 -0.08: 8.3 mm

- l1 +0.6: 35 mm

- d2: 9.65 mm

- d3: 21.5 mm

- d4 min.: 10.05 mm

- l2 ±0.5: 8.75 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 1.5 kN

- Load capacity according to DIN EN 13155 F2: 1.2 kN

- Load capacity according to DIN EN 13155 F3: 0.5 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 8.3 mm

- Operating temperature range max.: 250 °C

- Weight: 235 g

- d1 -0.04 -0.08: 10 mm

- l1 +0.6: 15 mm

- d2: 11.7 mm

- d3: 21.5 mm

- d4 min.: 12.2 mm

- l2 ±0.5: 10.2 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 2.7 kN

- Load capacity according to DIN EN 13155 F2: 2.4 kN

- Load capacity according to DIN EN 13155 F3: 2.1 kN

- x min.: 1.5 mm

- x max.: 10 mm

- Location hole H11: 10 mm

- Operating temperature range max.: 250 °C

- Weight: 277 g

- d1 -0.04 -0.08: 10 mm

- l1 +0.6: 25 mm

- d2: 11.7 mm

- d3: 21.5 mm

- d4 min.: 12.2 mm

- l2 ±0.5: 10.2 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 2.7 kN

- Load capacity according to DIN EN 13155 F2: 2.4 kN

- Load capacity according to DIN EN 13155 F3: 2.1 kN

- x min.: 1.5 mm

- x max.: 10 mm

- Location hole H11: 10 mm

- Operating temperature range max.: 250 °C

- Weight: 277 g

- d1 -0.04 -0.08: 10 mm

- l1 +0.6: 35 mm

- d2: 11.7 mm

- d3: 21.5 mm

- d4 min.: 12.2 mm

- l2 ±0.5: 10.2 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 2.7 kN

- Load capacity according to DIN EN 13155 F2: 2.4 kN

- Load capacity according to DIN EN 13155 F3: 2.1 kN

- x min.: 1.5 mm

- x max.: 10 mm

- Location hole H11: 10 mm

- Operating temperature range max.: 250 °C

- Weight: 299 g

- d1 -0.04 -0.08: 10 mm

- l1 +0.6: 50 mm

- d2: 11.7 mm

- d3: 21.5 mm

- d4 min.: 12.2 mm

- l2 ±0.5: 10.2 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 2.7 kN

- Load capacity according to DIN EN 13155 F2: 2.4 kN

- Load capacity according to DIN EN 13155 F3: 2.1 kN

- x min.: 1.5 mm

- x max.: 10 mm

- Location hole H11: 10 mm

- Operating temperature range max.: 250 °C

- Weight: 291 g

- d1 -0.04 -0.08: 12 mm

- l1 +0.6: 15 mm

- d2: 14.2 mm

- d3: 21.5 mm

- d4 min.: 14.7 mm

- l2 ±0.5: 11 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 3.5 kN

- Load capacity according to DIN EN 13155 F2: 3.2 kN

- Load capacity according to DIN EN 13155 F3: 2.8 kN

- x min.: 1.5 mm

- x max.: 10 mm

- Location hole H11: 12 mm

- Operating temperature range max.: 250 °C

- Weight: 282 g

- d1 -0.04 -0.08: 12 mm

- l1 +0.6: 25 mm

- d2: 14.2 mm

- d3: 21.5 mm

- d4 min.: 14.7 mm

- l2 ±0.5: 11 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 3.5 kN

- Load capacity according to DIN EN 13155 F2: 3.2 kN

- Load capacity according to DIN EN 13155 F3: 2.8 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 12 mm

- Operating temperature range max.: 250 °C

- Weight: 289 g

- d1 -0.04 -0.08: 12 mm

- l1 +0.6: 35 mm

- d2: 14.2 mm

- d3: 21.5 mm

- d4 min.: 14.7 mm

- l2 ±0.5: 11 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 3.5 kN

- Load capacity according to DIN EN 13155 F2: 3.2 kN

- Load capacity according to DIN EN 13155 F3: 2.8 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 12 mm

- Operating temperature range max.: 250 °C

- Weight: 299 g

- d1 -0.04 -0.08: 12 mm

- l1 +0.6: 50 mm

- d2: 14.2 mm

- d3: 21.5 mm

- d4 min.: 14.7 mm

- l2 ±0.5: 11 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 3.5 kN

- Load capacity according to DIN EN 13155 F2: 3.2 kN

- Load capacity according to DIN EN 13155 F3: 2.8 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 12 mm

- Operating temperature range max.: 250 °C

- Weight: 309 g

- d1 -0.04 -0.08: 13.8 mm

- l1 +0.6: 25 mm

- d2: 16.2 mm

- d3: 21.5 mm

- d4 min.: 16.7 mm

- l2 ±0.5: 13 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 3.8 kN

- Load capacity according to DIN EN 13155 F2: 3.5 kN

- Load capacity according to DIN EN 13155 F3: 2.8 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 13.8 mm

- Operating temperature range max.: 250 °C

- Weight: 302 g

- d1 -0.04 -0.08: 13.8 mm

- l1 +0.6: 50 mm

- d2: 16.2 mm

- d3: 21.5 mm

- d4 min.: 16.7 mm

- l2 ±0.5: 13 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 3.8 kN

- Load capacity according to DIN EN 13155 F2: 3.5 kN

- Load capacity according to DIN EN 13155 F3: 2.8 kN

- x min.: 1.5 mm

- x max.: 35 mm

- Location hole H11: 13.8 mm

- Operating temperature range max.: 250 °C

- Weight: 360 g

- d1 -0.04 -0.08: 13.8 mm

- l1 +0.6: 75 mm

- d2: 16.2 mm

- d3: 21.5 mm

- d4 min.: 16.7 mm

- l2 ±0.5: 13 mm

- l3: 25.7 mm

- l4: 36 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 87.5 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 3.8 kN

- Load capacity according to DIN EN 13155 F2: 3.5 kN

- Load capacity according to DIN EN 13155 F3: 2.8 kN

- x min.: 1.5 mm

- x max.: 35 mm

- Location hole H11: 13.8 mm

- Operating temperature range max.: 250 °C

- Weight: 391 g

- d1 -0.04 -0.08: 16 mm

- l1 +0.6: 25 mm

- d2: 18.6 mm

- d3: 25 mm

- d4 min.: 19.2 mm

- l2 ±0.5: 15.1 mm

- l3: 31 mm

- l4: 44.5 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 92.8 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 4.8 kN

- Load capacity according to DIN EN 13155 F2: 4.5 kN

- Load capacity according to DIN EN 13155 F3: 4.1 kN

- x min.: 1.5 mm

- x max.: 15 mm

- Location hole H11: 16 mm

- Operating temperature range max.: 250 °C

- Weight: 385 g

- d1 -0.04 -0.08: 16 mm

- l1 +0.6: 50 mm

- d2: 18.6 mm

- d3: 25 mm

- d4 min.: 19.2 mm

- l2 ±0.5: 15.1 mm

- l3: 31 mm

- l4: 44.5 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 92.8 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 4.8 kN

- Load capacity according to DIN EN 13155 F2: 4.5 kN

- Load capacity according to DIN EN 13155 F3: 4.1 kN

- x min.: 1.5 mm

- x max.: 35 mm

- Location hole H11: 16 mm

- Operating temperature range max.: 250 °C

- Weight: 424 g

- d1 -0.04 -0.08: 16 mm

- l1 +0.6: 75 mm

- d2: 18.6 mm

- d3: 25 mm

- d4 min.: 19.2 mm

- l2 ±0.5: 15.1 mm

- l3: 31 mm

- l4: 44.5 mm

- l5: 27 mm

- l6: 30 mm

- l7: 49 mm

- l8: 92.8 mm

- l9: 21.5 mm

- Load capacity according to DIN EN 13155 F1: 4.8 kN

- Load capacity according to DIN EN 13155 F2: 4.5 kN

- Load capacity according to DIN EN 13155 F3: 4.1 kN

- x min.: 1.5 mm

- x max.: 40 mm

- Location hole H11: 16 mm

- Operating temperature range max.: 250 °C

- Weight: 467 g

- d1 -0.04 -0.08: 20 mm

- l1 +0.6: 50 mm

- d2: 24.5 mm

- d3: 30 mm

- d4 min.: 25.2 mm

- l2 ±0.5: 19.7 mm

- l3: 36.5 mm

- l4: 52 mm

- l5: 32.6 mm

- l6: 36 mm

- l7: 56 mm

- l8: 114 mm

- l9: 26 mm

- Load capacity according to DIN EN 13155 F1: 10 kN

- Load capacity according to DIN EN 13155 F2: 8.5 kN

- Load capacity according to DIN EN 13155 F3: 6.5 kN

- x min.: 1.5 mm

- x max.: 25 mm

- Location hole H11: 20 mm

- Operating temperature range max.: 250 °C

- Weight: 709 g

- d1 -0.04 -0.08: 20 mm

- l1 +0.6: 75 mm

- d2: 24.5 mm

- d3: 30 mm

- d4 min.: 25.2 mm

- l2 ±0.5: 19.7 mm

- l3: 36.5 mm

- l4: 52 mm

- l5: 32.6 mm

- l6: 36 mm

- l7: 56 mm

- l8: 114 mm

- l9: 26 mm

- Load capacity according to DIN EN 13155 F1: 10 kN

- Load capacity according to DIN EN 13155 F2: 8.5 kN

- Load capacity according to DIN EN 13155 F3: 6.5 kN

- x min.: 1.5 mm

- x max.: 30 mm

- Location hole H11: 20 mm

- Operating temperature range max.: 250 °C

- Weight: 776 g

Material

Pin part

- Heat-treated steel, tempered, manganese phosphated

Press button

- Aluminium, red anodised

Shackle

- Heat-treated steel, tempered, manganese phosphated

Spring

- Stainless Steel

Assembly

Simple H11 boreholes are sufficient.

Mounting:

- Press in the button and hold it down

- Insert the lifting pin

- Release the button (The button must be back in its original position)

Dismantling:

- Press in the button and hold it down.

- Remove the lifting pin.

- Release the button.

Operation

Each lifting pin contains an instruction manual with an EC Declaration of Conformity.

Accessories

As accessories, we offer matching locating bushings for d1 = 8, 10, 12, 16 and 20

Further products

- Lifting Pins, self-locking, stainless steel

- Locating Bushings, for lifting pins

- Locating Bushings, plain, for lifting pins

- Locating Bushings with Seal, plain, for lifting pins

- Threaded Lifting Pins, self-locking

- Threaded Lifting Pins, self-locking, for centre holes according to DIN 332

- Threaded Lifting Pins, self-locking, with rotatable shackle

- Threaded Lifting Pins, self-locking - INCH

- Threaded Lifting Pins, self-locking, with rotatable shackle - INCH

RoHS compliant

Contains lead - compliant according to exceptions 6a / 6b / 6c.

Contains SVHC substances >0,1% w/w

Contains lead - SVHC list [REACH] as of 27.06.2024.

Contains Proposition 65 substances

Lead can cause cancer and reproductive harm from exposure

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.

What is the difference between lifting pins and threaded lifting pins?

Components that have an existing thread can be moved or lifted with the threaded lifting pin. The lifting pins can be mounted very quickly in existing holes with undercuts. If no undercut is possible, e.g. with thin-walled parts or soft support material, an associated locating bushing can be used.

What to consider when mounting the lifting pins?

Tolerance H11 is sufficient for the locating hole. The lifting pin must always be inserted completely into the hole. As this is a TÜV-certified load lifting device with CE marking, the operating instructions must be observed.

What is the maximum axial load to which the lifting pins may be subjected?

The maximum load capacity varies with the version used. The values - tested in accordance with DIN EN 13155 - range from 1.5 kN (diameter 8) to 10 kN (diameter 20). The values range lower for a diagonal pull / tensile direction of 90° - see product data table.

From which quantity can a special geometry be produced for the lifting pins?

An economical offer can be made for orders of 10 or more. Please feel free to send us your enquiry if required.

What is the difference between the TÜV certificate and the CE marking for lifting pins and threaded lifting pins?

As the threaded lifting pins and lifting pins are load lifting device and thus fall within the scope of the Machinery Directive 2006/42/EC, CE marking is mandatory. The CE marking includes, among other things, that a maximum load capacity of the lifting pins and/or threaded lifting pins is specified. This information is determined by internal calculations and tests. The lifting pin or threaded lifting pin receives a TÜV approval only if these values have also been tested and approved by the TÜV. Special designs are only manufactured as special pins without CE marking and thus without indication of the load capacity, as no tests and calculations are usually effected for them. If necessary, a CE marking can be issued if the lifting pin or threaded lifting pin is similar to a standard lifting pin and its load data can be used as a reference. A TÜV certificate must be specially ordered from the TÜV for each size and is accompanied by additional costs. Please send us your enquiry if required.

Are the details on the lifting pins an indication of the production batch?

Yes, in addition to the annual production date, the respective serial number S/N is also indicated on the lifting pin.

Of what materials are the lifting pins made?

There is a version made of heat-treated steel, tempered, manganese phosphated and a version made of stainless steel 1.4542 precipitation hardened, depending on the area of application. For load values see product data table.

What is the service life of a lifting pin?

This is not possible to answer in a general way, as it always depends on the application and the environmental influences. If a lifting pin is damaged, e.g. if it is cracked or deformed, it must be removed from use immediately. This visual and functional check must be carried out before each use. Furthermore, the lifting pin must be subjected to a safety check once a year, including a visual and functional check by a qualified person.

Can the lifting pins be used for personal protection?

The lifting pins have no approval to be used for the protection of persons. If the lifting pins should be used for this purpose, the lifting pin must be specially approved as a personnel hoist by the manufacturer of these products.